As technology advances, so will all its components. Precision manufacturing is the umbrella term that focuses on executing the most precise functioning of manufacturing. It is made up of business models that improve the workplace and technical tools. Such as various forms of automation introduced into the workplace. Precision manufacturing aims to produce the best quality, design, and components for various machinery. Precision manufacturing has the power to change the way industries operate.

One of the most sought-after forms of precision manufacturing is high-tech tools. Tools that demonstrate precision, improve production and efficiency. However, a lot goes into these tools. For example, take a CNC router. Multiple components go into this machinery. Such as the computer system, cutting pad, and spindle, to name only a few. Every little aspect of that machine will be scrutinized and improved repeatedly. This is the goal of precision manufacturing always to be the most precise in everything related to manufacturing tools.

What Is A CNC Machine?

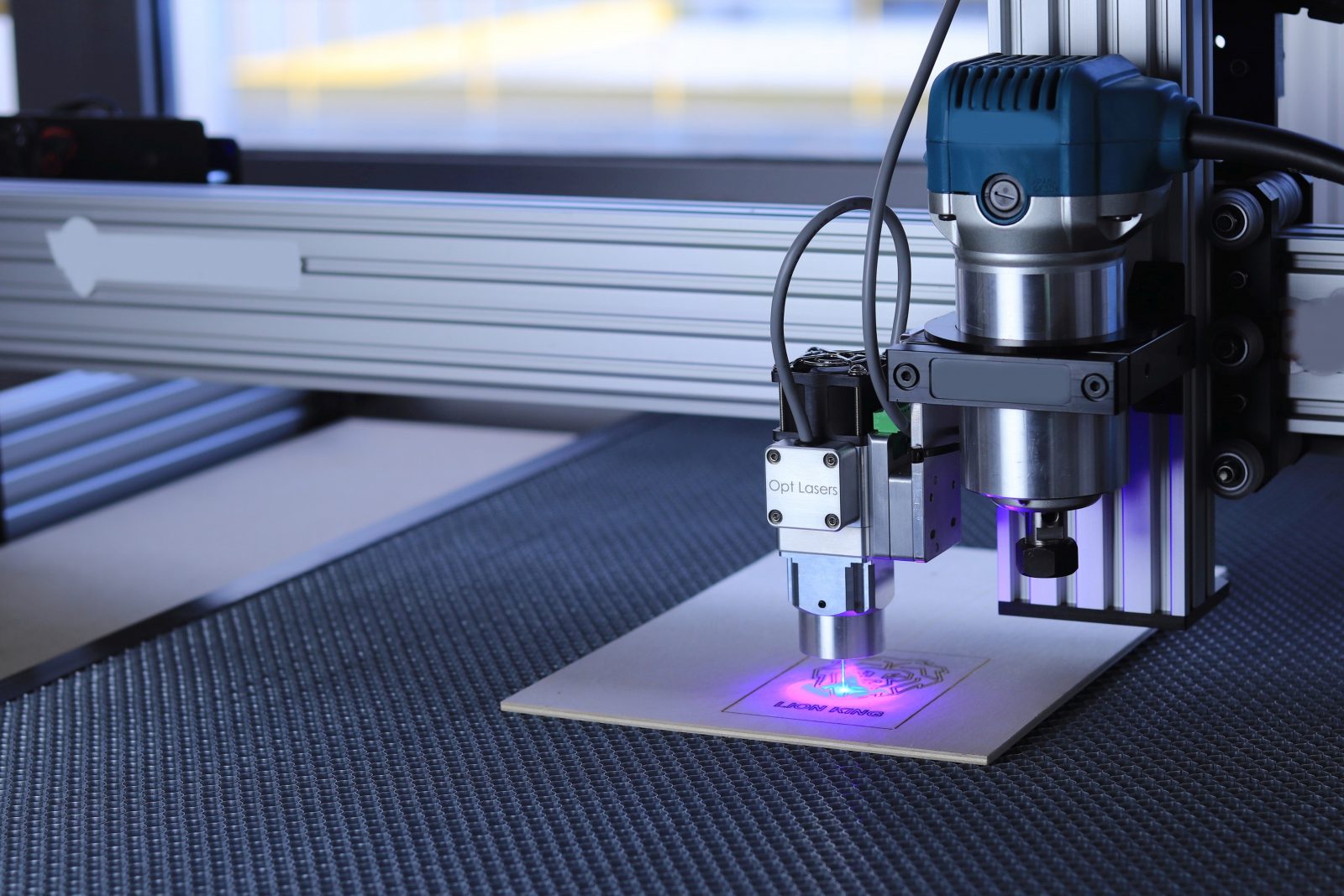

A CNC machine is one of the best forms of precision manufacturing due to its extreme precision. A CNC router is a machine that creates a physical product made from raw materials. The materials typically consist of aluminum, resin, or plywood.

The machines work in unison with computer software such as CAD, which produces either 2D or 3D designs. The program is then programmed into the CNC machine. The CNC machine uses its components to create a replica of the plan bringing it to life.

The machines are fully computerized and efficient in every form. Human error is limited alongside preventing injuries. It’s a popular machine that many industries use today to improve precision manufacturing.

Why Precision Manufacturing Improves Business

Today, businesses are flocking to industries that use CNC machines. They have numerous benefits than previous business models, such as:

- Precision – CNC machines limit human error. They can run entirely on their own without the need for humans to interfere. The machines are far more accurate than any human can produce.

- Creates Jobs – Although CNC machines can produce the product independently, they cannot control themselves, which means workers learn how to design and operate it. There are jobs available for the workforce that are not labor-intensive and teach the employee how to run high-tech materials.

- Improves Manufacturing – One machine can produce numerous products per day. Multiple devices make hundreds if not thousands of units a day. This speeds up production and improves manufacturing within hours.

Precision Manufacturing

Companies strive to improve precision manufacturing through CNC machines. Such as Aerospace Machine Shop. The components that make up a CNC machine are complicated yet valuable. Fortunately, every update to the machine offers quick transferable knowledge from the previous version. However, it’s essential to keep up to date with the various forms of precision manufacturing. Staying on top of things allows a business to continue to grow. With automation expanding, it is vital to continue to grow with it.

Leave a Reply