ABSTRACT

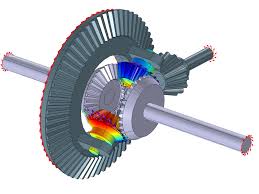

The main objective of this paper is to perform mechanical design of differential gear

box and analysis of gears in gear box. We have taken grey cast iron and aluminium alloy

materials for conducting the analysis. Presently used materials for gears and gears shafts

is Cast Iron, Cast Steel. So, in this paper we are checking as the aluminum can be the other

material for the differential gear box for light utility vehicles so, we can reduce the weight.

Key words: Differential Gear Box, Structural Analysis, Design and Structural Analysis of

Differential Gear Box

1. INTRODUCTION

A differential is a gear train with three shafts that has the property that the angular velocity of one

shaft is the average of the angular velocities of the others, or a fixed multiple of that average. A

gear box provides speed and torque conversions from a rotating power source to another device

using gear ratios. In automobiles and other wheeled vehicles, the differential allows the outer drive

wheel to rotate faster than the inner drive wheel during a turn. This is necessary when the vehicle

turns, making the wheel that is traveling around the outside of the turning curve roll farther and

faster than the other. The average of the rotational speed of the two driving wheels equals the input

rotational speed of the drive shaft. An increase in the speed of one wheel is balanced by a decrease

in the speed of the other. When used in this way, a differential couples the input shaft (or prop

shaft) to the pinion, which in turn runs on the ring gear of the differential. This also works asreduction gearing. On rear wheel drive vehicles, the differential may connect to half-shafts inside

an axle housing, or drive shafts that connect to the rear driving wheels. Front wheel drive vehicles

tend to have the pinion on the end of the main-shaft of the gearbox and the differential is enclosed

in the same housing as the gearbox. There are individual drive-shafts to each wheel.

2. OBJECTIVES OF PRESENT WORK

We are creating the frictional contact between two mating gears. And we are doing the structural

analysis on gear box by providing the torque to the sun gear in the differential gear box.

Leave a Reply