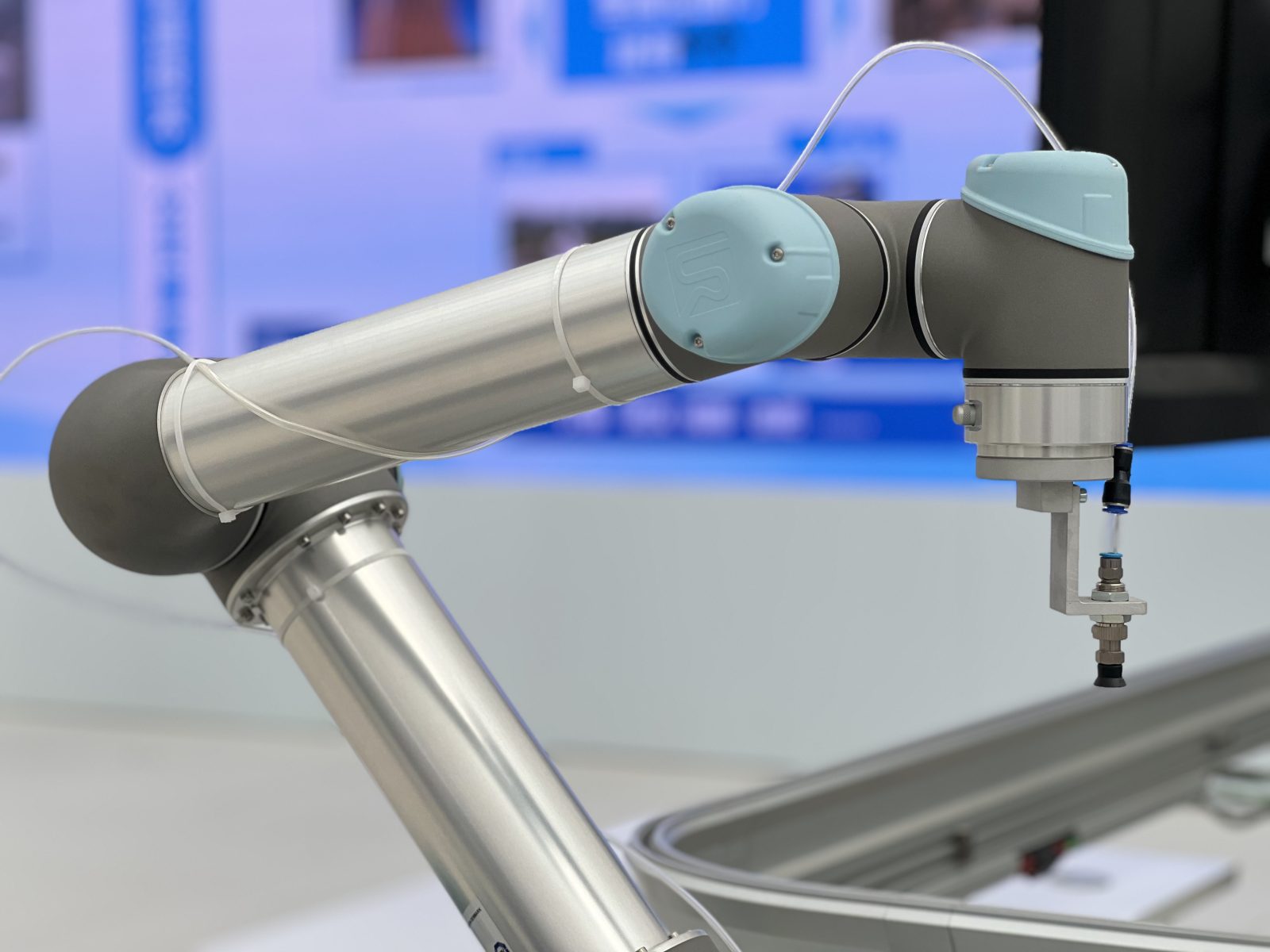

Robotic systems have become an integral part of modern-day manufacturing processes, and industrial robotic arms play a crucial role in the automation of assembly lines. These arms are multi-functional, versatile, and highly efficient, making them an essential tool for various industries. Huntsville, Alabama, is a hub for manufacturing and robotics, with several companies specializing in the development and production of industrial robotic arms. In this blog post, we will explore the uses of an industrial robotic arm that revolutionize manufacturing processes.

Precision Welding

Industrial robotic arms are ideal for precision welding tasks. They are highly accurate, and their repeatability allows for consistent results, ensuring a high-quality finish. Industrial robotic arms can perform multiple types of welding, including TIG, MIG, and laser welding. These arms can operate in hazardous environments, such as high temperatures or toxic fumes, making them ideal for use in the automotive and aerospace industries. Furthermore, robotic arms can be programmed to perform specific welding patterns, allowing for the efficient and precise production of complex parts.

Material Handling

Industrial robotic arms are capable of lifting and moving heavy loads with ease, making them an ideal tool for material handling. They can be programmed to work in conjunction with other robotic systems, such as conveyors, to automate the movement of materials throughout the production process. This capability allows for improved efficiency and safety in the workplace, as robotic arms can perform tasks that are too heavy or dangerous for human workers. Additionally, robotic arms can be programmed to handle delicate or fragile materials, ensuring that they are moved and processed without damage.

Painting and Coating

Industrial robotic arms are ideal for painting and coating tasks. They can be programmed to apply paint or coating to specific areas of a product, ensuring a high-quality finish. Additionally, robotic arms can apply the coating with a consistent thickness, improving the overall appearance and durability of the finished product. Robotic arms can also be used to apply coatings to products that are difficult or dangerous for human workers to reach. This use of industrial robotic arms is common in the automotive and aerospace industries, where high-quality finishes are essential.

Inspection and Quality Control

Industrial robotic arms can be used for inspection and quality control tasks, ensuring that products meet the required standards. These arms can be equipped with cameras and sensors, allowing them to detect and identify defects in products. Robotic arms can also be programmed to perform precise measurements, ensuring that products meet the required specifications. This use of industrial robotic arms reduces the risk of human error and improves the accuracy and speed of inspections.

Assembly

Industrial robotic arms can be programmed to perform complex assembly tasks. They can handle a variety of materials, including plastics, metals, and composites, and can assemble parts with high accuracy and speed. Robotic arms can also be used to assemble parts that are difficult or impossible for human workers to assemble. Additionally, robotic arms can be programmed to assemble products with different configurations, allowing for increased flexibility in the manufacturing process.

Conclusion

Industrial robotic arms are versatile, efficient, and highly effective tools for modern-day manufacturing processes. Their multi-functional capabilities allow for increased efficiency, accuracy, and safety in the workplace. Huntsville, Alabama, is a hub for robotic systems, with several companies specializing in the development and production of industrial robotic arms. As manufacturing processes continue to evolve and become more complex, the use of industrial robotic arms will become increasingly essential.

Leave a Reply