ABSTRACT

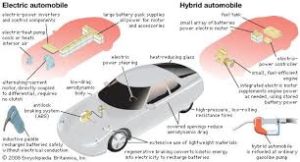

Pollution is the major problem in the universe, air pollution being one of the

predominant among them. Air pollution is mainly caused due to the exhaust gases

coming out of the vehicles and Industries. This is caused mainly due to burning of fuel

and gases emanating from chimneys. In an effort to control this pollution, a

combination of bio-degradable materials have been selected to absorb major

pollutants namely Carbon Dioxide (CO2), Carbon Monoxide (CO), Sulphur Dioxide

(SO2) and Hydro Carbons (HC) from automobile vehicles.

Experimental work has been carried out on a four stroke petrol engine with the

help of exhaust gas analyser. The readings are tabulated and plotted. It is observed

that the absorbers are absorbing the gases effectively during the period of

investigation.

Key words: Automobile exhausts, Absorbers, Gas Analyser

1. INTRODUCTION

Air pollution is caused by poisonous gases, sulphur dioxide, nitrogen dioxide, carbon

monoxide and very small particulates. It is also caused by the smoke and harmful gases

released by the fires and factories. Use of coal, wood and kerosene as fuels for fire also causes

air pollution. Air pollution may cause breathing problems such as asthma or other health

hazards. It also causes diseases like cancer. Table – 1 gives different types of pollution and

their damage.

2. AUTOMOBILE POLLUTANTS AND THEIR ABSORBERS

Particulate Matter (PM). These particles of soot and metals give smog its murky colour.

Fine particles less than one-tenth the diameter of a human hair pose the most serious threat to

human health, as they can penetrate deep into lungs. PM is a direct (primary) pollution. Diesel

exhaust is a major contributor to PM pollution.

Hydrocarbons (HC). These pollutants react with nitrogen oxides in the presence of sunlight

to form ground level ozone, a primary ingredient in smog. Though beneficial in the upper

atmosphere, at the ground level this gas irritates the respiratory system, causing coughing,

choking, and reduced lung capacity.

Nitrogen oxides (NOx). These pollutants cause lung irritation and weaken the body’s

defences against respiratory infections such as pneumonia and influenza. In addition, they

assist in the formation of ground level ozone and particulate matter.

Carbon monoxide (CO). This odourless, colourless, and poisonous gas is formed by the

combustion of fossil fuels such as gasoline and is emitted primarily from cars and trucks.

When inhaled, CO blocks oxygen from the brain, heart, and other vital organs. Foetuses, newborn

children, and people with chronic illnesses are especially susceptible to the effects of

CO.

Sulphur dioxide (SO2). Power plants and motor vehicles create this pollutant by burning

sulphur-containing fuels, especially diesel. Sulphur dioxide can react in the atmosphere to

form fine particles and poses the largest health risk to young children and asthmatics.

Hazardous air pollutants (toxics). These chemical compounds have been linked to birth

defects, cancer, and other serious illnesses. The Environmental Protection Agency estimates

that the air toxics emitted from cars and trucks which include Benzene, acetaldehyde, and 1,

3-butadiene account for half of all cancers caused by air pollution.

Greenhouse gases. Motor vehicles also emit pollutants, such as carbon dioxide, that

contribute to global climate change. In fact, cars and trucks account for over one-fifth of

global warming pollution. Transportation, which includes freight, trains, and airplanes,

accounts for around thirty percent of all heat-trapping gas emissions.

Much of the vehicular air pollution can be avoided by maintaining proper speed of the

vehicles. Vehicles stranding on the road crossing or in traffic jams cause more pollution. The

quantity of harmful emissions decreases with increasing speed as given in Table 2

3. FABRICATION AND TESTING OF PROTOTYPE

For most common hazardous pollutants, absorbing materials which bio-degradable are

selected

4.COST ANALYSIS

The cost analysis has been presented for exposed area of exhaust gas absorbers of size 190 x

150 x 12 mm3. Each plank of absorber costs ₹ 117 /- for carbon monoxide and ₹ 27 /- for

sulphur oxides, carbon di-oxide and hydrocarbons.

Total cost of the absorbers is ₹ 144 /- (Excluding the cost of wood) for the selected size of

2 planks. The cost is in direct relation to the size of absorber planks that can be arranged in

the real environment.

5. CONCLUSIONS

In this project an attempt has been made to fabricate and investigate experimentally, an

exhaust gas absorbing device. The absorbers selected based on the exhaust gases are

commercially available and also economical for easy replacement over a definite period of

time interval. The set-up fabricated is found to be effective to absorb exhaust gases during the

period of investigation.

Leave a Reply Cancel reply

Categories

- Animal27

- Apps3

- Art70

- Auto50

- Business175

- Career1

- Education114

- Faith62

- Family186

- Fashion35

- Food67

- Gadgets16

- Gaming13

- Health139

- Hobby134

- Holidays26

- Home96

- Legal11

- Marketing40

- Money96

- News30

- News130

- Other Stories4

- Pet1

- Photography14

- Poem23

- Science28

- SkyPip3

- Social Network75

- Society159

- Software23

- Technology125

- Travel69

Leave a Reply